FLY ASH IMPOUNDMENT CLOSURE AND DAM MODIFICATION

For this 300-acre wet fly ash impoundment closure, ENTACT conducted a multiyear phased approach for the project. Closure construction started with draining surface water via pumping or digging temporary drainage channels in the deposited ash to direct water to an area immediately behind the main dam. As we managed the surface water, we excavated the exposed fly ash and relocated and/or regraded the surface to meet subgrade elevations across the site. Work progressed from the highest to lowest elevations across

ACTIVE REFINERY PROCESS UNIT PROPOSED LOCATION

ENTACT performed soil remediation and ground improvement to address low-pH soils because of a sulfuric acid spill at the refinery. The ground needed to be stabilized to support the construction of a new process unit at the site. Subsurface soils consisted of saturated, soft, and sandy clay on top of very soft clay. ENTACT performed ISS on approximately 86,000 cubic yards from 22 to 24 feet below ground to strengthen this area. Using a combination of granulated ground blast furnace

FORMER WOOD PRESERVING SITE REMEDIAL ACTION

This 84-acre wood preserving site was added to the National Priorities List in 1997, due to contaminated groundwater, soil, and sediment from over 30 years of wood treating operations. While multiple cleanup phases had occurred over the years, the prior remedy was deemed inadequate, and ISS was selected as the revised remedy. The scope of work included conducting an ISS demonstration before full-scale implementation; removing, stockpiling, and replacing clean, overburden soils; ISS of 15,400 cubic yards of non-aqueous phase liquids

FORMER MANUAFACTURED GAS PLANT (MGP) SITE REMEDIAL ACTION

ENTACT remediated an MGP site located in an urban area bordered by light industrial and commercial development, undeveloped land, and a shallow river. Historical releases of MGP residuals had impacted soil and groundwater, and contaminants migrating to the adjacent river’s bank affected an isolated sediment area. The overall scope included the development of a treatability study; demolition of concrete footings and slabs; excavation and off-site disposal of 10,500 tons of impacted soil; installation of 180 linear feet of 36-inch reinforced

FISHING CREEK SOUTH JETTY REHAB AND MAINTENANCE DREDGING

This project combines dredging and stone jetty improvements for the U.S. Army Corps of Engineers in Chesapeake Beach, MD. White Lake Dock & Dredge, Inc. (WLDD), a division of ENTACT, LLC, hydraulically dredged and conveyed more than 30,000 cubic yards of sediment from inner and outer harbors into a confined disposal facility (CDF). We also performed grading work and replaced the weir box outlet control structures inside the CDF. After the dredging, WLDD initiated jetty rock revetment work to repair

SANITARY LANDFILL NPL SITE

ENTACT was engaged to perform remediation services at a former sanitary landfill National Priorities List (NPL) site. The work area is approximately 2 acres in size and required the removal 23,800 cubic yards of impacted soil and more than 35,000 buried drums disposed of at the site in the early 1970s. Scope of work included the construction of a 200-foot-by-350-foot container management area pad; design and installation of a steel sheet pile wall to protect an existing soil-cement-bentonite slurry wall;

BROWNFIELD REDEVELOPMENT AREA REMEDIATION

ENTACT performed remediation activities at several blocks and lots at this site, representing a larger-area brownfield redevelopment project for future residences. Multiple industrial operations impacted the soil with the following contaminants of concern: polycyclic aromatic hydrocarbons (PAHs), volatile organic compounds (VOCs), polychlorinated biphenyls (PCBs), hexavalent chromium, chromium ore process residue (COPR), extractable petroleum hydrocarbon (EPH), pesticides, various metals and lead. Scope of work included design, procurement, and installation of a 1,600-linear-foot, 40-foot-deep permanent vertical hydraulic control system; dewatering, water treatment,

RARE EARTH PROCESSING FACILITY RADIOLOGICAL DECOMMISSIONING

ENTACT decommissioned, decontaminated, and demolished a former rare earth minerals processing plant in a larger chemical manufacturing complex. The site was approved for closure by the USEPA in 2015. Modeling was used to determine remediation goals for allowable soil concentrations to meet the regulatory requirement, which resulted in soil concentrations equal to 3 pCi/g of thorium-232 and 9 pCi/g uranium-238. Approximately 100,000 tons of radiologically impacted soil, sediment, construction debris, and 230,000 gallons of impacted water have been removed from

FORMER SMELTER MIXED-USE REDEVELOPMENT

ENTACT completed remedial action activities that included managing and consolidating onsite debris and decontamination and demolishing remaining smelter buildings. We regraded over 1.3 million cubic yards of slag and soil – slag piles as large as 8.5 acres and up to 50 feet tall – representing five separate slag categories distinguished by color and gradation for utilization in distinct sections of the development; removed the impacted soil and sediment; and constructed a 185-acre soil cover system over the entire site.

CANAL SEGMENT CONTAMINATED SEDIMENT REMEDIATION

ENTACT performed remediation of mercury- and lead-contaminated sediments from an approximate 3,600-linear-foot segment of a closed canal. A temporary remediation support area was constructed with two dredge processing cells, a temporary water pretreatment system area, multiple staging areas along the canal, and a temporary water management system to complete the task. We performed the mechanical dredging of ~30,000 cubic yards of sediment from a floating barge assembly, dewatering and conditioning of sediments, and characterization, transportation, and off-site disposal. ENTACT finished

FORMER OILFIELD AND SERVICE FACILITY EXCAVATION AND BACKFILL SERVICES

ENTACT performed remediation of soils impacted by volatile organic compounds (VOC), nonaqueous phase liquids (NAPL), and benzene, toluene, ethylbenzene, and xylene (BTEX) at this former oilfield and service facility. The scope of work included shallow excavation of 3,268 cubic yards of impacted soils followed by a self-hardening cement-bentonite slurry-supported excavation of 13,000 cubic yards of impacted soils up to 52 feet deep; transportation and off-site disposal of ~25,500 tons of excavated material; backfilling of affected areas with over 6,500 cubic yards; and

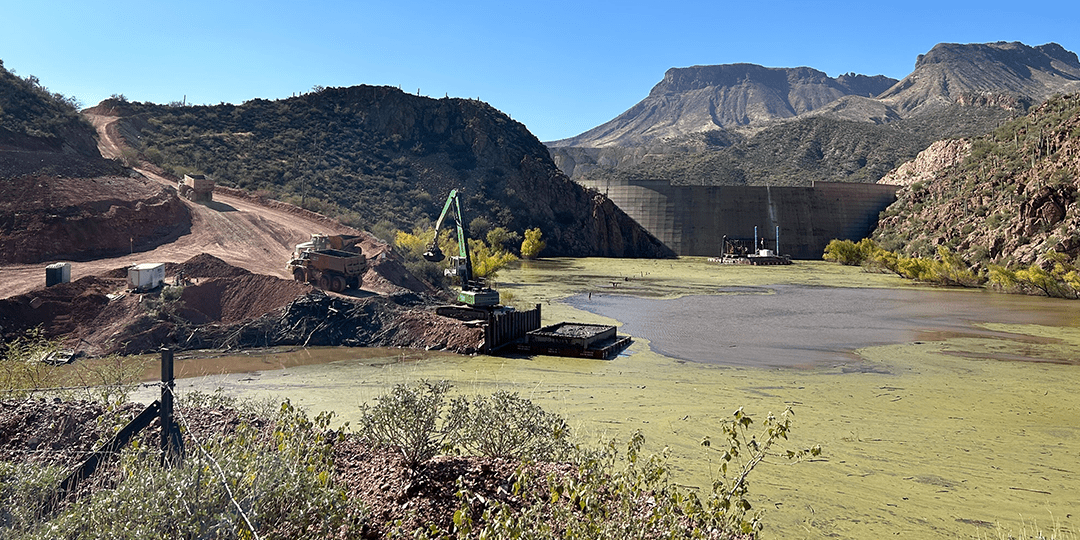

LAKE RESERVOIR DREDGING

White Lake Dock & Dredging, Inc. (WLDD), a division of ENTACT, LLC, conducted mechanical dredging of more than 120,000 cubic yards of contaminated sediments from a remote reservoir within an active mining operation. The client had water quality issues due to uncontrolled reservoir sediment that threatened the mining operation. The project’s remote location required the construction of access roadways, mobilization of equipment in a mountainous environment, transportation, and disposition of sediments with grades upwards of 17%, and unpredictable weather, including