FORMER MANUAFACTURED GAS PLANT (MGP) SITE REMEDIAL ACTION

ENTACT undertook the remediation of a former MGP site situated in an urban area, adjacent to light industrial and commercial developments, as well as undeveloped land and a shallow river. Historical releases of MGP residuals had contaminated soil and groundwater, leading to the migration of pollutants to the riverbank, affecting an isolated sediment area. During the project, ENTACT: Developed a treatability study Demolished concrete footings and slabs Excavated and disposed of 10,500 tons of impacted soil off-site Installed180 linear feet

FISHING CREEK SOUTH JETTY REHAB AND MAINTENANCE DREDGING

This project was performed by White Lake Dock & Dredge, a division of ENTACT. Scope of work involved both dredging and stone jetty improvements for the U.S. Army Corps of Engineers. All work was conducted in a shallow tidal environment, ensuring compliance with environmental standards. Throughout this project, our team: Dredged more than 30,000 cubic yards of sediment from inner and outer harbors and conveyed it to a confined disposal facility (CDF) Graded and replaced weir box outlet control structures

BAYFRONT REDEVELOPMENT

ENTACT completed a comprehensive multi-phase remediation of a 100-acre industrial site located near a river, preparing it for mixed-use redevelopment. This project focused on the removal of hazardous materials, groundwater management, and site restoration to ensure compliance with environmental standards. Phase 1: Central Area Remediation The first phase spanned three and a half years and concentrated on the central portion of the site. This phase involved the excavation and removal of significant amounts of chromium ore process residue (COPR) and

SANITARY LANDFILL NPL SITE

ENTACT was engaged to perform remediation services at a former sanitary landfill National Priorities List site spanning approximately two acres. The project required the removal of 23,800 cubic yards of impacted soil and the disposal of over 35,000 buried drums that had been discarded at the site in the early 1970s. On this project, ENTACT: Constructed a 200-foot by 350-foot container management area pad Designed and installed a steel sheet pile wall to protect an existing soil-cement-bentonite slurry wall Constructed

BROWNFIELD REDEVELOPMENT AREA REMEDIATION

ENTACT performed remediation activities across several blocks and lots as part of a larger brownfield redevelopment project aimed at future residential use. The site was impacted by multiple industrial operations, leading to soil contamination with various hazardous substances, including polycyclic aromatic hydrocarbons (PAHs), volatile organic compounds (VOCs), polychlorinated biphenyls (PCBs), hexavalent chromium, chromium ore process residue (COPR), extractable petroleum hydrocarbons (EPH), pesticides, metals, and lead. For this project, ENTACT: Designed, procured, and installed a 1,600-linear-foot, 40-foot-deep permanent vertical hydraulic control

RARE EARTH PROCESSING FACILITY RADIOLOGICAL DECOMMISSIONING

ENTACT decommissioned, decontaminated, and demolished a former rare earth minerals processing plant within a larger chemical manufacturing complex. The site received TXDSHS remediation plan approval in 2015. Through modeling and calculations, it was determined that a gradient approach to allowable soil concentrations (DCGLs) ranging from 5 pCi/g of thorium-232/Ra-226 and 83 pCi/g uranium-238, to 500 pCi/g Th-232/Ra-226 and U-238 would be used. 100,000 tons of radiologically impacted soil, sediment, and construction debris and 230,000 gallons of impacted water were removed

LOGISTICS PARK DEVELOPMENT

ENTACT completed comprehensive soil and groundwater remediation activities at a former coal-fired power generating station contaminated with polychlorinated biphenyls (PCBs), hexavalent chromium (Cr(VI)), chromium ore process residue (COPR), and extractable petroleum hydrocarbons (EPH). These contaminants were present at levels exceeding cleanup criteria, necessitating remediation for future site development. Throughout this project, ENTACT: Excavated, segregated, and characterized hazardous (TSCA and RCRA) and non-hazardous soil for off-site treatment and disposal Installed 7,500 square feet of a steel sheet pile cutoff wall using

FORMER SMELTER MIXED-USE REDEVELOPMENT

ENTACT executed comprehensive remedial action activities at a former smelter site, focusing on managing and consolidating onsite debris, as well as decontaminating and demolishing the remaining smelter buildings. On this project, ENTACT: Regraded more than 1.3 million cubic yards of slag and soil, including slag piles as large as eight acres and up to 50 feet tall Distinguished five separate slag categories by color and gradation for targeted utilization in various sections of the development Removed impacted soil and sediment

CANAL SEGMENT CONTAMINATED SEDIMENT REMEDIATION

ENTACT executed the remediation of mercury and lead contaminated sediments along a 3,600-linear-foot segment of a closed canal. This project involved the construction of a temporary remediation support area and several key operational components to ensure effective sediment removal and management. Our team successfully addressed sediment contamination and enhanced the ecological and recreational value of the canal area. On this project, ENTACT: Constructed a temporary remediation support area with two dredge processing cells, a temporary water pretreatment system area, multiple

FORMER OILFIELD AND SERVICE FACILITY EXCAVATION AND BACKFILL SERVICES

ENTACT conducted remediation activities at a former oilfield and service facility to address soils impacted by volatile organic compounds (VOCs), nonaqueous phase liquids (NAPL), and BTEX (benzene, toluene, ethylbenzene, and xylene). This project effectively remediated the contaminated site, preparing it for potential future use. On this project, ENTACT: Excavated 3,268 cubic yards of impacted soils Performed self-hardening cement-bentonite slurry-supported excavation of 13,000 cubic yards of impacted soils Transported and disposed of 25,500 tons of excavated material off-site Backfilled affected areas

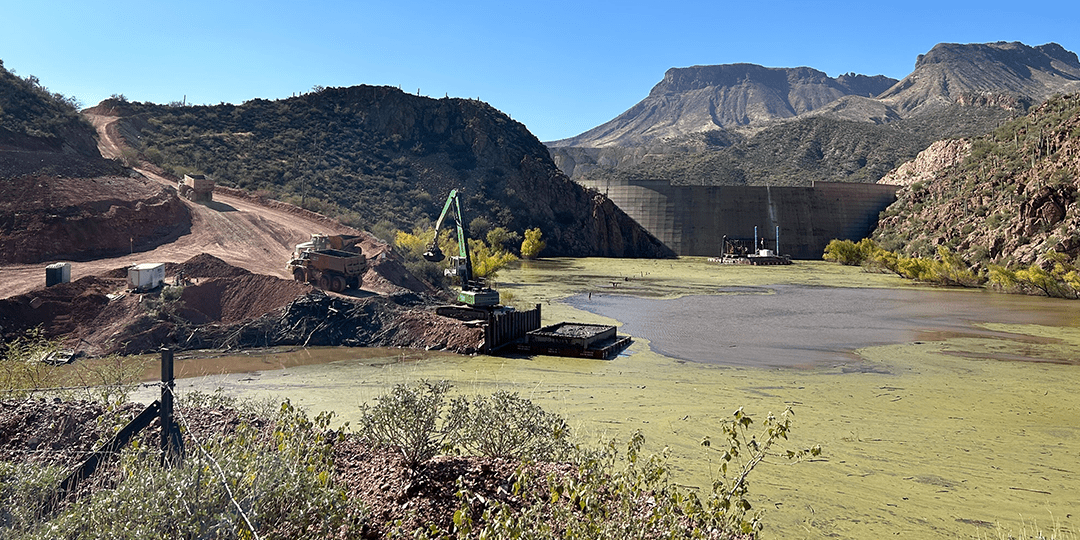

LAKE RESERVOIR DREDGING

White Lake Dock & Dredge, a division of ENTACT, undertook the mechanical dredging of more than 120,000 cubic yards of contaminated sediments from a remote reservoir within an active mining operation. The project addressed critical water quality issues stemming from uncontrolled reservoir sediment that posed a threat to the mining operations. This project was completed successfully despite the challenging conditions, ensuring the continued operational integrity of the mining site. Our team: Constructed access roadways to facilitate equipment mobilization in a

MANISTEE RIVER MGP REMEDIATION

White Lake Dock & Dredge, a division of ENTACT, executed the dredging of 30,000 cubic yards of manufactured gas plant (MPG)-impacted sediment from a half mile stretch of the Manistee River. The sediments were solidified with Portland cement in lined dewatering pits prior to disposal at the landfill. This project was successfully completed while navigating the complexities of a busy waterway, ensuring environmental compliance and operational efficiency. On this project, our team: Dredged 30,000 cubic yards of MGP-impacted sediment Managed