Dewatering and water treatment

Effective dewatering and water management is essential to the success of environmental remediation and geotechnical construction projects. At ENTACT, we bring decades of field-proven experience managing groundwater, surface water, and process liquids in support of a wide range of site development, remediation, and restoration efforts. Our in-house teams self-perform dewatering and water treatment tasks across diverse project settings, from active industrial sites to large-scale environmental remediation programs.

Our dewatering capabilities

ENTACT implements a variety of proven techniques to control water during excavation and construction activities. Our capabilities include:

- Fixed Well Point Extraction Systems – Installation, operation, and removal of systems that control shallow groundwater levels to maintain dry work zones.

- Portable Point Source Dewatering – Deployment of vacuum trucks, pumps, and sump systems to manage localized water accumulation.

- Deep Well Systems and Groundwater Diversion – Advanced methods for long-term or high-volume groundwater control, including biopolymer trenching and deep drain networks.

- Barrier Technologies – Construction of vertical slurry walls, steel/vinyl/fiberglass sheet pile walls, and deep soil mixing barriers to limit groundwater flow into excavation areas.

- Soil Moisture Reduction – Use of in-situ mixing with drying reagents to reduce water content in soil and improve workability.

Our teams ensure compliance with all National Pollutant Discharge Elimination System (NPDES) requirements by integrating water quality monitoring, discharge permitting, and best available treatment designs and practices as part of our dewatering efforts.

Water treatment services

Water treatment is often a critical component of environmental remediation and geotechnical construction projects. ENTACT delivers custom-built systems that treat accumulated groundwater, stormwater, and process liquids—either for on-site discharge or off-site disposal. We support both temporary and long-term treatment system needs with construction, commissioning, and operations. ENTACT leverages the local market to complete the onsite construction and commissioning of our systems. We often self-perform the process operation and are supported locally with our corrective and preventative maintenance needs.

Our treatment systems address:

- Organic Constituents – Including suspended solids reduction, multi-media filtration, carbon adsorption, coagulation and flocculation, advanced oxidation processes, and other clarification processes.

- Inorganic Constituents – Such as metals precipitation, sediment filtration, ion exchange, multi-media applications, and reverse osmosis.

- Non-Aqueous Phase Liquids (NAPL) – Techniques include oil-water separation, free-product recovery, air stripping, adsorption, and oxidation methods.

- Stormwater – Management and treatment systems for runoff collection, filtration, and regulatory compliance.

Water treatment systems range from 50 to 2,500 gallons per minute (GPM) and are designed for flexibility, durability, and cost efficiency. ENTACT selects and integrates system components based on site-specific parameters, discharge criteria, and anticipated flow rates. We work closely with experienced equipment suppliers, local subcontractors, and licensed operators to support every phase of treatment system execution.

Groundwater remediation expertise

ENTACT delivers comprehensive groundwater remediation services tailored to support project goals and regulatory compliance. Our teams apply a broad suite of technologies and best practices to manage dissolved and free-phase constituents in subsurface environments.

Our experience includes:

- Light and Dense Non-Aqueous Phase Liquid (LNAPL and DNAPL) recovery

- Dual-phase extraction and soil vapor recovery

- In-situ chemical oxidation and reduction

- Microbial augmentation and bio-stimulation

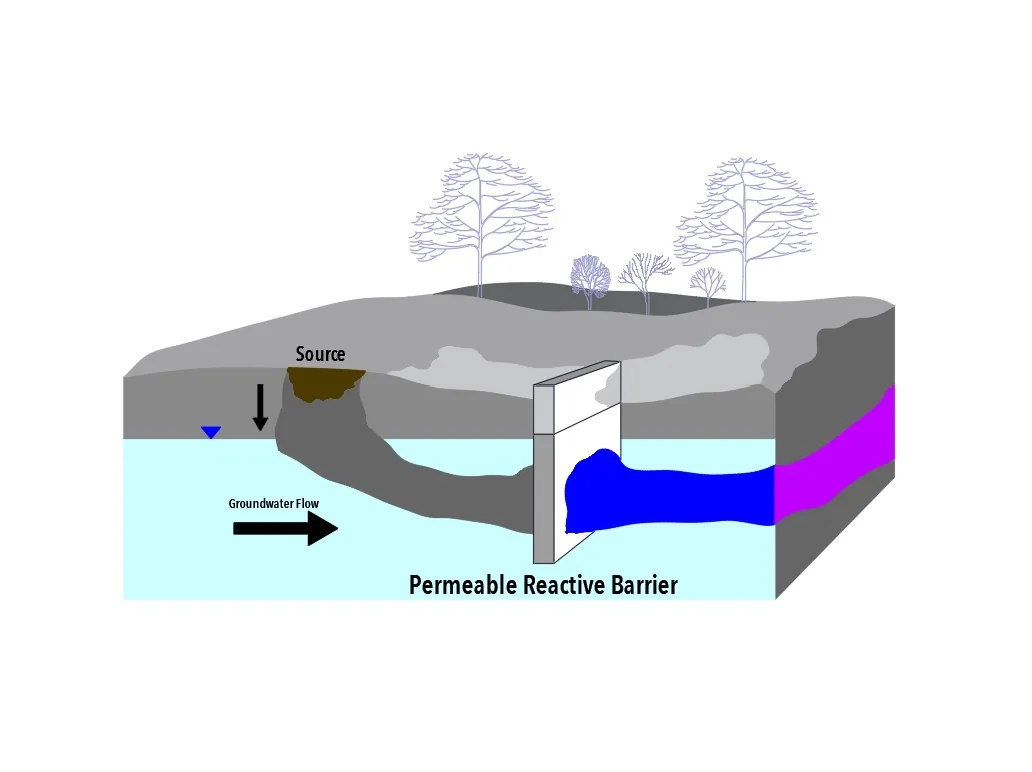

- Zero Valent Iron (ZVI) injection and permeable reactive barrier (PRB) installation

- Groundwater and wastewater treatment systems

- Passive and active monitoring systems

We use hydrogeological assessments, fate and transport modeling, and natural attenuation studies to inform project planning and decision-making. Our work supports industrial facilities, municipal programs, and large-scale federal projects governed by the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) and the Resource Conservation and Recovery Act (RCRA).

Why ENTACT?

- Self-Performance – ENTACT self-performs the construction oversight, operation, and maintenance of dewatering and water treatment systems using our personnel and equipment.

- Local Market Cost Effectiveness – ENTACT utilizes the local market to perform specialized trades such as electrical and mechanical to provide our clients with the most cost-effective construction and commissioning approach to our systems.

- Turnkey Solutions – We manage all aspects of system deployment, from equipment procurement and installation to monitoring and demobilization.

- Field-Driven Expertise – Our teams have decades of hands-on experience and are supported by dedicated subject matter experts in water treatment and remediation.

- Regulatory Familiarity – We ensure compliance with NPDES discharge requirements and partner closely with regulatory stakeholders to support permitting and reporting.

- Custom Approaches – Every solution is tailored to the specific site conditions, water chemistry, and operational goals to ensure cost-effective and high-performance outcomes.

Frequently asked questions

Dewatering is the process of removing groundwater or surface water to create dry working conditions. Water treatment involves removing physical, chemical, or biological substances from water to meet discharge or reuse criteria.

Yes. We self-perform system operations and maintenance, often under the supervision of licensed personnel when required by state regulations.

We manage and treat groundwater, stormwater, and process liquids generated during remediation or construction activities.

Yes. We tailor treatment systems to meet project-specific discharge criteria, using technologies that address a wide range of water quality parameters.